Somerset Weaving Mill Acquired by Local Firm

Roger Yeoman • 30 December 2020

Wells Journal - Friday 18 January 1929

Image © Reach PLC. Image created courtesy of THE BRITISH LIBRARY BOARD.

From 1797 to 1929. Somerset Weaving Mill Acquired by Local Firm.

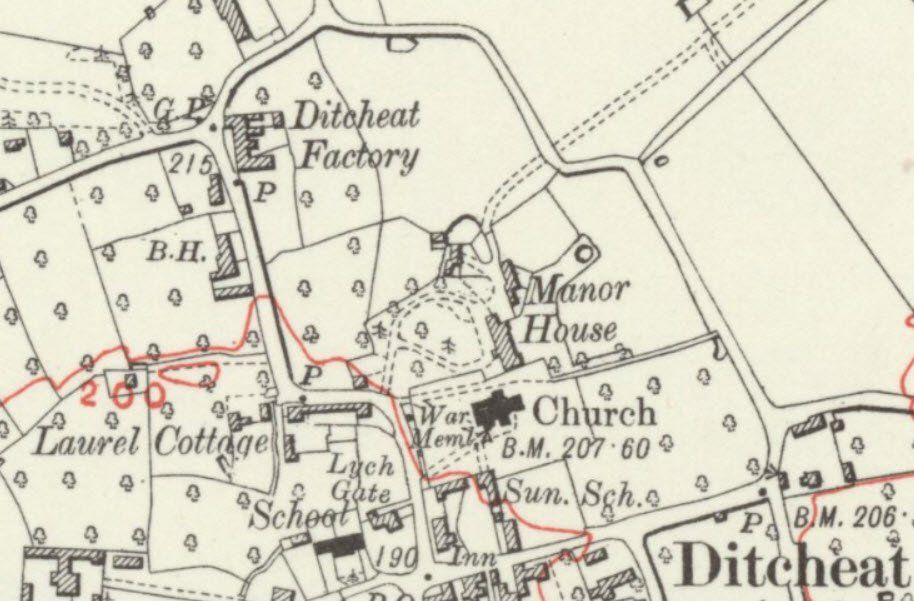

In the quaint old-world village of Ditcheat which lies between Shepton Mallet and Castle Cary, and a mile or so from Evercreech, there are several points of interest to the visitor. The fine old church with its lych gate will immediately attract. This is the church of St. Mary Magdalene, built in the Perpendicular style, but originally Norman. Nearby is the Priory, a large building in the Gothic style and originally attached to the Abbey of Glastonbury. It is built in the Gothic style and was originally moated and had large tithe barns and buildings. In field a short distance from the village is a petrifying spring called the Holy Well.”

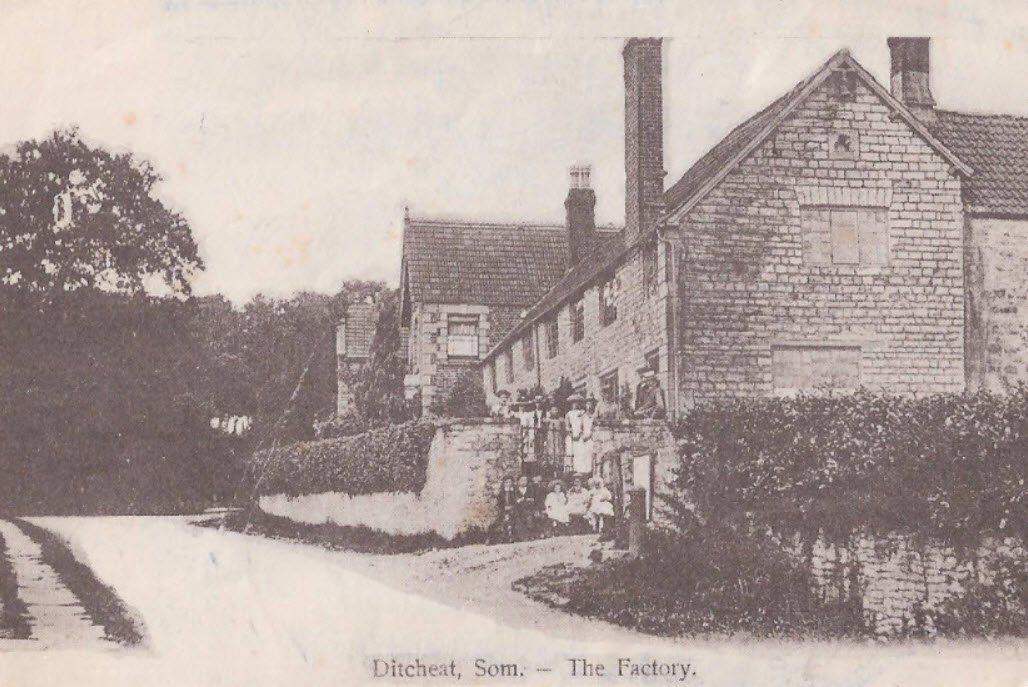

Walking down through the village street, if we may be allowed to use this description of the main thoroughfare, we come to a large group of buildings, too large for a farmhouse or for the usual type of village industry. Curiosity prompts us to enquire as to the industry carried on in this peaceful spot, and we naturally show some surprise when told that it is a weaving mill. Upon reflection we can well understand that the Ditcheat weaving mill is one of the few remaining in the rural districts of the country. With the advent of industrial centralisation the majority of mills scattered all over Britain were either abandoned or adapted for other purposes. Not so with Ditcheat, however, for this factory always had a good local market for its goods, since its inception in 1797.

POWER WEAVING INTRODUCED

Originally there were three mills—at Ditcheat’ Bruton and Evercreech. The one at Bruton is now transformed into Messrs. Hendersons, Iron Works the one at Evercreech now being Messrs. Hill’s Cheese Stores, whilst the mill at Ditcheat retained for the manufacture of textiles suitable for the dairy industry. It is interesting to note that in those days the mill was worked by one of the old steam beam engines. In 1879 Edwin King introduced power weaving machinery which had revolutionised the weaving industry all over the country

With the introduction of an electrical generating plant and the fitting of electric light throughout the mill in 1909. the Ditcheat mill became quite a model factory and it can easily claim to be the only factory of its kind in the country for the manufacture of specialised textiles required for the milk producing and cheese making industies

The first proprietor of this mill was Mr. George King, who travelled all over the county selling the goods he manufactured.

The same industry carried on in the same premises has been handed down from generation to generation until the death of Edwin King, during the early days of the War, when his son was in the Navy, and of course, on active service, for which reason the business was sold to Mr. T. G. Vincent, the present representative of an old family of yeoman farmers. Thus was the continuity of ownership broken after a period extending over 130 years.

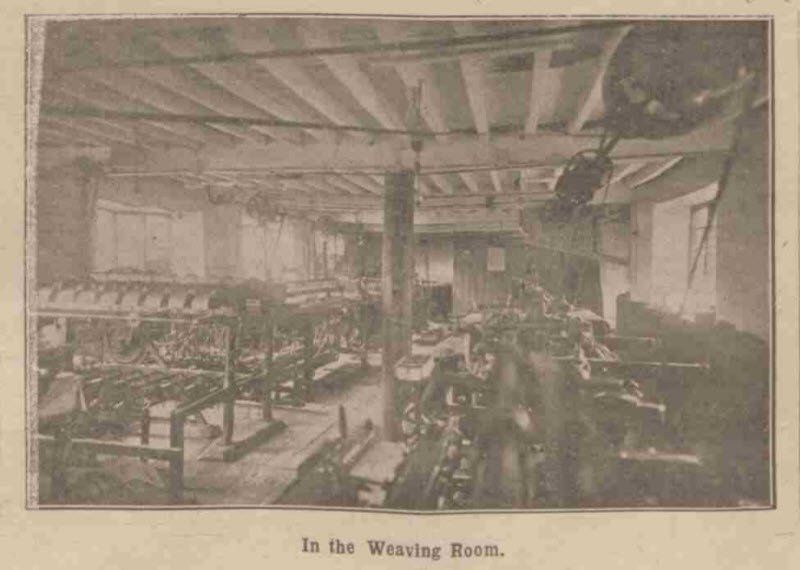

During our visit to the Ditcheat Factory we were surprises to notice under what pleasant conditions the workers carry out their duties. Light, airy workrooms with a view from the windows so full of rural beauties, that a Lancashire lassie would turn green with envy, if she could have a peep at the Ditcheat Mill.

DAIRY TEXTILES.

In walking through the weaving room, it was noticed that various cloths were in the course of manufacture Cheese Cloth in the “flat,” and in the single and double “tubes” Linen cheese strainer cloth, linen cheese banding and many others which were not familiar. In another part the factory cheese caps for export were being cut in thousands, whilst roller bandages very similar to the surgical variety, were being cut and rolled from large pieces of material for a special method of cheese banding practised in Scotland and elsewhere. The goods made by this old established firm are of the highest excellency, and the workers carrying on their daily duties are working under the most pleasant conditions. Rent, Rates and Taxes and general overhead charges being so extremely small, it is not to be wondered at that not only is the very best work turned out from this Factory, but more important still to those who are issuing the goods upon a far lower cost than can possibly be produced in a more expensively equipped factory and in a higher rated district.

COLONIES SUPPLIED.

It is, therefore, not surprising that the Ditcheat Factory has been so successful in supplying goods continuously for many years to some of the largest wholesale firms in London, Manchester, Birmingham and the Colonies.

The firm of Clares Dairy Textiles Specialists have been the pioneers for the supply of special and suitable materials for dairy use, and the acquisition of this Somerset factory will considerably assist them in supplying every need in this respect. The Ditcheat factory will be of great utility in research work for fabrics suitable for the dairying industry, and thus the many thousands of their customers will know that everything sold by Clares is subject to exhaustive tests before, during, and after manufacture.

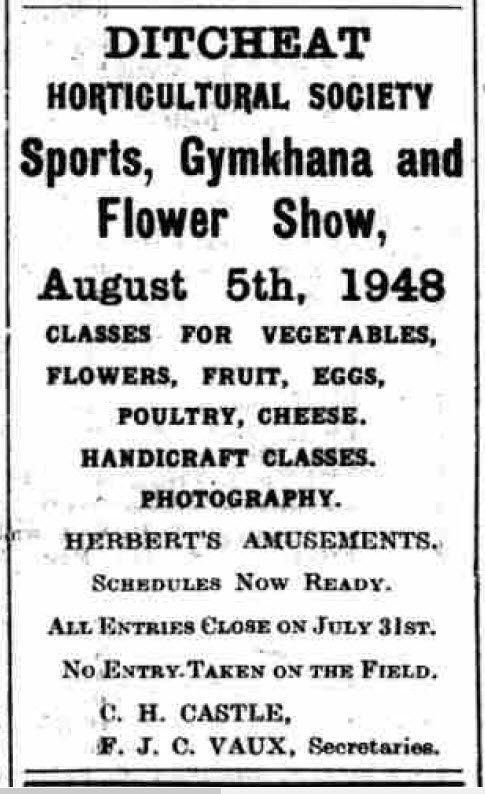

News paper report of the 1948 Show This blog post is prompted by my visit to the 135th Hawkesbury Horticultural Society Show in South Gloucester, it is believed to be one of the longest continuously running Horticultural Shows in England. From its start in 1885, to the 134th Show in the summer of 2019, it had been held every year without a break. The Ditcheat Show folded in the early 60's . This report is of a show that I cannot remember, being not quite 1 year old. However, I do recall many of the shows in my childhood and competed in the children's section.

This post was prompted by a response to this website from Denise Graham, she wrote "Both my husband & myself worked for John Wainwrights over at Stoke St Michael, Many years ago a large brass 'nut' was found (for the wheel of a horse drawn stone waggon). It is stamped with "Ditcheat Waggon Works Shepton Mallet(t). ? Padfield & Son(s). It has been 'persuaded' on and off with a chisel, so some letters are unclear. Would you know any history of Padfields Waggon works? " During my childhood the business in the centre of Ditcheat was run by Mitchell & Hill Builders & Undertaker, wheelwrights, smithy and wagon building had stopped. Although I remember the Tyring Platform present in the yard. The first record I found from the newspaper archives dated January 1890 is of William Hodges advertising for a blacksmith.

A few people will remember the dilapidated wall along the Grove footpath pre 1992, when you could just step over a pile of stones into the orchard. It was not economical to repair as far as the agricultural use would justify and the ownership was questionable, a problem that was often raised at Parish Council. One day when Norris Yeoman was cleaning along the path surface and edges a car pulled up at the end and this chance meeting led to the wall being rebuilt. The gentleman was a representative of Bovis and was looking for projects to put forward for the government's Employment Action scheme, where unemployed people would volunteer minimum of 32¼ hours per week and receive £10 per week over and above their DSS benefits. A scheme was approved and the Parish Funded the materials with contribution from the farmer, Earnest Dyke. A large van body was purchased and used as a site store and cabin. There was a set back when the men's tools were stolen from the lock up store. The next night the hired mixer was also stolen. A villager loaned his mixer, more tools were forthcoming and within a few days £365 was collected in the village to replace the original tools.

The quarry was in existence since from about 1870 and was generally described as producing “Blue Lias Lime and Selenitic Cement”, but in Kelly’s Directory of 1902, it also claims Portland cement. The opening of the quarry quickly followed the completion of the Burnham to Evercreech section of the Somerset & Dorset Railway in 1862 During the next 40 years the quarry was operated by a number of owners, this page reproduces advertisements and newspaper reports of events and court cases. It is interesting reading and is an insight to the industrial heritage in Pylle and the local area. The newspaper reports were researched from www.britishnewspaperarchive.co.uk with additional information from www.cementkilns.co.uk/cement_kiln_pylle.html Maps are found at The National Library of Scotland which has more editions of OS maps including the First Edition maps from 1884, use this link ,

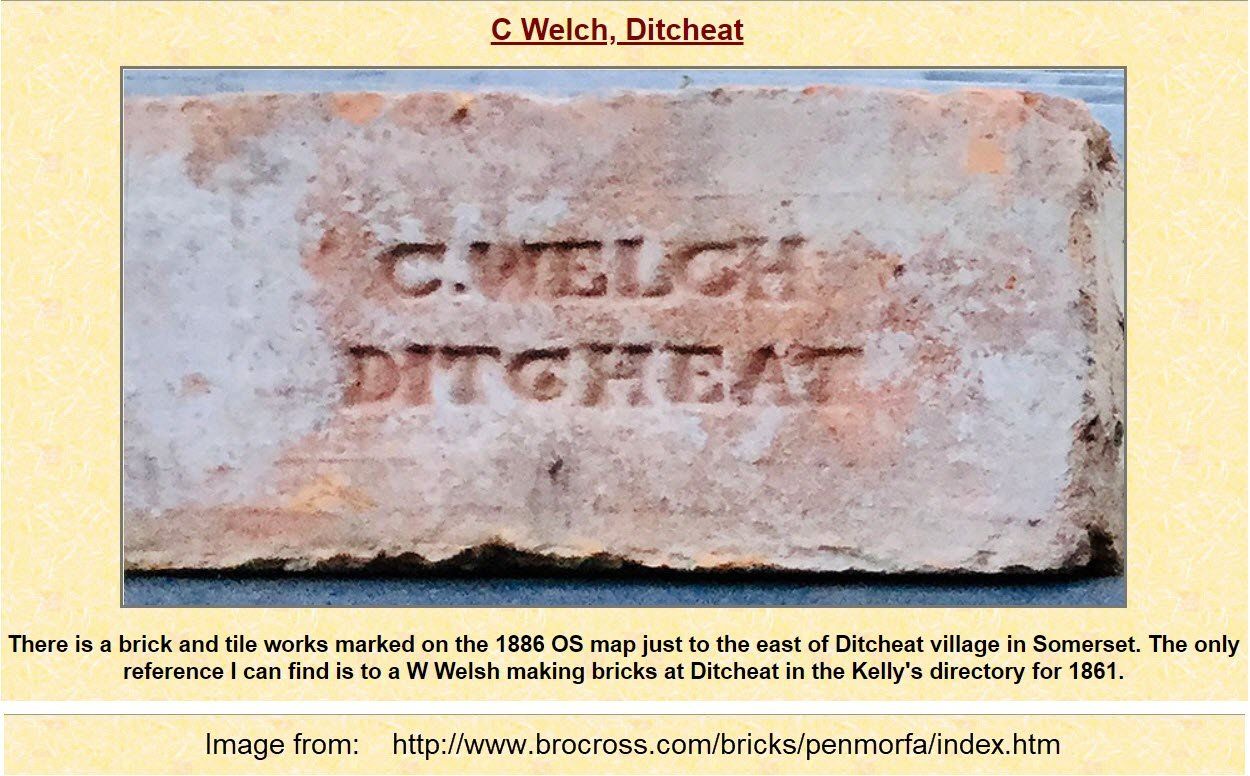

Examples of Ditcheat bricks stamped "C Welch" can be found in a number of walls around the village. The location of the brick works is shown on an 1884 map available at https://maps.nls.uk/view/106022273 The works are missing in the 1928 revision https://maps.nls.uk/view/101461624 The area worked covered the whole of the site now occupied by the houses on the east side of Folly Drive. Clay was excavated to the level of the rear gardens right up to the front gate of the present houses. The houses are build on made up ground, mostly with the surplus trench spoil arising from the installation of mains drainage in the village around 1958.

Shepton Mallet Journal - Friday 05 February 1926 Image © Reach PLC. Image created courtesy of THE BRITISH LIBRARY BOARD. DITCHEAT. Farewell Gathering. —A very pleasant evening was spent at the Green tree Inn,” on Friday last, on the occasion the departure of the Post Office Linesmen, who have, for this last three months, been residing in the village during the installation new lines. Mr. George Merrifield, speaking for the villagers, said that the company the linesmen would be greatly missed, and that if they should happen to return to the district at some, future date, they might be sure of very hearty welcome. Mr. Bert Lockyer, replying on behalf the linesmen, spoke highly of Ditcheat hospitality, and .said that they would always live in the hope of returning to the village, if only for short stay. The Ditcheat Jazz Band, which was in attendance during the evening, and rendered excellent music, was ably led Mr. Herbert Mintern.